Understanding Concrete Spalling in High-Rise Structures

Concrete spalling is one of the most serious and frequently overlooked threats to the structural health of Australia’s aging high-rise buildings. In many urban centres, particularly Sydney , a significant number of towers built between the 1970s and early 2000s are now exhibiting signs of spalling—ranging from cracking and delamination to exposed steel reinforcement. According to industry estimates, up to 40% of older high-rise buildings in coastal regions face some form of concrete degradation. This deterioration not only affects the building’s appearance but also undermines its structural integrity, increases risk exposure, and leads to rising insurance premiums.

For strata committees and facility managers, taking early, professional action is the most effective way to mitigate future costs and ensure safety. to the structural integrity of Australia’s aging high-rise buildings. Across cities like Sydney, Adelaide, and the Gold Coast, many tall structures built from the 1970s through the early 2000s are now exhibiting tell-tale signs of deterioration. This includes cracking, flaking, and exposed rebar—clear indications that spalling is compromising both aesthetic appeal and structural soundness.

Once concrete begins to fail, the damage typically accelerates. Spalling doesn’t just affect appearances—it weakens key structural elements, introduces potential safety risks for occupants and passers-by, and contributes to dramatically rising insurance premiums. For strata committees, building managers, and commercial asset owners, the pressure to act early and decisively has never been greater.

What Causes Concrete Spalling?

Concrete spalling can be triggered by a range of environmental and structural factors, particularly in high-rise buildings exposed to harsh conditions. Moisture-related causes include water ingress that seeps into cracks and corrodes embedded steel reinforcement, along with chloride contamination and salt crystallisation in coastal zones. Construction-related factors such as insufficient concrete cover, poorly formulated concrete mixes, and incompatible surface finishes also play a major role. Thermal expansion and contraction further contribute to long-term wear. Grouping these conditions helps us better understand how each can accelerate structural degradation if left unaddressed.

Common Triggers of Concrete Spalling

- Water ingress seeping into cracks and corroding embedded steel reinforcement

- Insufficient concrete cover or poorly formulated concrete mixes

- Use of incompatible surface finishes or sealants

- Repeated thermal expansion and contraction

- Coastal exposure leading to chloride contamination and salt crystallisation

Concrete spalling is a progressive issue. What might begin as minor flaking can escalate into serious structural degradation without timely intervention.

High-rise Sign Repairs

Addressing the specific challenges of high-rise sign repairs, our services include inspection reports for concrete spalling, concrete cancer repair in the Gold Coast, high-rise maintenance in Sydney CBD and Parramatta, concrete facade repairs, and facade system maintenance and repair in Adelaide. We also provide maintenance work for high-rise buildings in Sydney, concrete remediation and repairs in the Gold Coast, concrete restoration in Sydney, addressing concrete crack repairs as well.

We also provide high-rise painting services that protect building exteriors from weathering and maintain a clean, professional appearance over time.

Visible Cracks or Spalling Concrete

- Cracks, flaking, or chunks of concrete falling from façades or balconies are major red flags. They can indicate corrosion of steel reinforcement or structural weakness requiring immediate attention.

Water Ingress or Staining

- Damp patches, rust streaks, or efflorescence (white salt deposits) on exterior walls suggest water is seeping through the façade — often due to failed sealants, joints, or membranes.

Loose or Deteriorating Cladding and Fixtures

- Panels, tiles, or fixtures that appear loose, corroded, or detached pose serious safety risks. These issues often worsen with wind or weather exposure and need professional inspection.

Corrosion or Rusting Around Balconies and Metal Elements

- Rust marks or corroded balustrades can mean moisture is penetrating the structural frame. Over time, this compromises both safety and aesthetics.

Discolouration, Mould, or Peeling Paint on Façades

- These cosmetic changes often signal deeper issues — like trapped moisture or failing coatings — and are early warnings of façade deterioration.

Why Remedial Repair, Not Cosmetic Fixes

Quick surface repairs and patching may provide a temporary aesthetic improvement, but they rarely address the underlying causes of concrete deterioration. In fact, superficial fixes can sometimes trap moisture or worsen corrosion over time.

True remediation requires a deeper, more strategic approach. At CPR, our advanced concrete restoration services are tailored for high-rise building concrete repair, targeting the root causes of spalling. Our repair methodology involves removing all compromised material, treating corroded reinforcement, and rebuilding with structural-grade concrete repair compounds designed to withstand high-rise stressors and harsh environmental exposure.

We combine these robust repair techniques with non-invasive access systems, allowing our team to carry out complex repairs without disrupting daily operations or tenant privacy.

Request an Expert Consultation →

Our Scaffold-Free™ Concrete Spalling Repair Approach

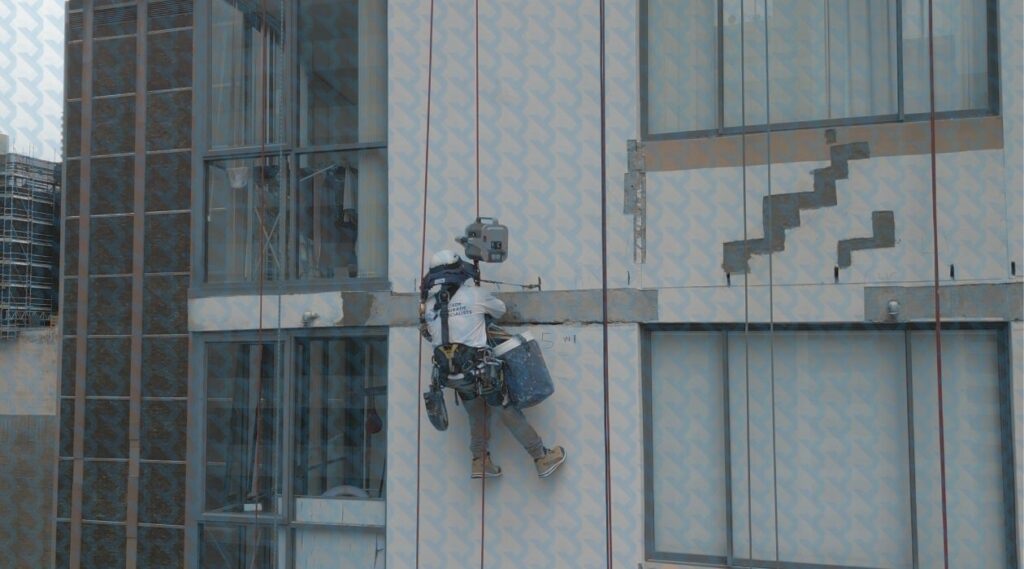

At CPR, we’ve moved beyond traditional scaffolding. One recent project involved a 22-storey commercial tower in Sydney’s CBD where our team was able to complete structural patching and full coating reinstatement using MARS™ and PEARS® systems—all without erecting scaffolding or interrupting tenants. This approach reduced both project time and cost, while maintaining complete privacy and access for building users. Our Scaffold-Free™ model is supported by a suite of proprietary access technologies that allow our technicians to carry out complex, high-level repairs without cumbersome external structures.

- MARS™ (Multiple Access Rope System): A fully integrated rope access system anchored to the building for agile movement across any facade.

- PEARS® (Portable Elevation Access Rope System): A powered elevation system that supports vertical movement and load transportation.

- SkyPod® BRMW: An encapsulated, dust-controlled mobile workstation that enhances safety, cleanliness, and repair efficiency.

These access systems integrate seamlessly with our SFS360® diagnostic platform. This system allows us to divide building facades into a detailed grid, map each defect by type and severity, and generate a precise project scope—from planning through execution.

Advanced Solutions for Concrete Spalling in High-Rise Buildings

There is no one-size-fits-all solution to concrete spalling—especially in high-rise buildings where access, structural load, and exposure to the elements all vary. At CPR, we use a suite of advanced methods tailored to each scenario:

1. Patch Repair (Hand-Applied Mortar)

- Use: Minor surface spalling

- Process: Damaged concrete is removed, steel reinforcement cleaned or treated, then patch mortar is applied.

- Pros: Cost-effective and quick

- Cons: Limited durability for deeper or widespread damage

2. Epoxy Injection

- Use: Cracks and internal spalling without extensive rebar exposure

- Process: Low-viscosity epoxy is injected into cracks to bond concrete and restore strength.

- Pros: Structural bonding and crack sealing

- Cons: Doesn’t address ongoing corrosion if steel is already rusting

3. Cathodic Protection

- Use: Severe spalling due to active steel corrosion

- Process: Uses electric current to halt corrosion by converting rebars into cathodes

- Pros: Long-term protection ideal for highly exposed structures

- Cons: Higher upfront cost; best suited for large-scale or high-rise applications

4. Recasting or Shotcrete

- Use: Extensive surface loss or structural section failures

- Process: Concrete is sprayed (shotcrete) or re-cast using formwork to rebuild volume

- Pros: Durable and strong

- Cons: Requires skilled labour and longer curing times

5. Anti-Carbonation or Waterproof Coatings

- Use: As a final protective layer after repairs

- Process: Surface coatings prevent moisture and CO₂ ingress

- Pros: Increases lifespan of repairs and prevents new spalling

- Cons: Not a standalone solution—must follow full substrate preparation

6. Rebar Replacement or Treatment

- Use: When steel reinforcement is severely corroded

- Process: Rusted rebars are replaced or treated with inhibitors/coatings before patching

- Pros: Prevents recurrence of spalling

- Cons: Requires deeper concrete excavation and careful reinstatement

Best Practice for High-Rise Buildings: For large structures exposed to high winds, salt air, or heavy rainfall, we often combine methods—such as patch repair, rebar treatment, and protective coatings. In severe cases, cathodic protection systems paired with waterproof coatings offer the most sustainable, long-term outcomes.

Sustainable and Long-Term Concrete Repair Solutions

Our approach is grounded in real-world practicality. We use long-lasting, sustainable materials and systems that stand up to the demands of Australia’s climate and regulatory standards.. We prioritise materials and methods that deliver real-world resilience, not just theoretical performance.

- Application of engineering-grade concrete remediation compounds

- Use of corrosion-inhibiting treatments and alkali restoration to protect rebar and internal concrete structure

- Deployment of weather-tolerant protective coatings tailored to each building’s location and elevation

- Emphasis on non-disruptive service delivery for tenants, visitors, and businesses

This well-rounded strategy delivers genuine value—solving today’s concerns while reinforcing your building’s safety, durability, and appearance for years to come.

Explore Our Full Remediation Approach →

Where We Operate

CPR offers full-service concrete spalling repair across NSW, ACT, SA, and other regions where high-rise building stock requires expert intervention. Our team collaborates with consultants, engineers, strata managers, and developers to design remediation programs that meet each site’s unique conditions and constraints.

From spalling damage repair, to water ingress remediation in Sydney, or complete facade remediation in coastal areas, we bring technical precision and scaffold-free efficiency to every job.

Why Choose CPR for Your High-Rise Spalling Repairs?

- Over 30 years of hands-on experience in high-rise façade repair and maintenance

- Total project ownership through our SE2EPC® end-to-end model

- Internal workforce trained and certified via our PEARS® Elevation Academy

- Accreditation under ASP’S™ – Accredited Service Partners

- Transparent, photographic reporting and documentation of every stage

- Post-project support through AfterCare™

We’re here to safeguard your building’s future—not just through fixes, but by delivering smarter, more resilient facade solutions backed by decades of on-the-ground experience.

Book a Consultation Today

Concrete cancer doesn’t fix itself. Left untreated, it worsens over time—posing safety hazards, increasing liability, and leading to skyrocketing remediation costs. The earlier you act, the more you save—in costs, in risk, and in peace of mind. CPR’s scaffold-free, engineering-grade remediation systems are trusted by clients across the commercial, strata, government, and heritage sectors.