Introduction

AS4654.2 External Waterproofing: Key Standards for Long-Lasting Protection sets the benchmark for external above-ground waterproofing in Australia. The standard ensures that buildings—particularly high-rise and difficult-access structures—are protected against water ingress, structural deterioration, and premature failures. Understanding and complying with AS4654.2 is essential for architects, builders, engineers, and strata committees seeking durable, cost-effective, and regulation-compliant external waterproofing solutions.

This guide explores the critical elements of AS4654.2, explains why compliance matters, and highlights waterproofing best practices that deliver long-lasting protection for commercial, strata, industrial, and government assets.

Why AS4654.2 External Waterproofing Standards Matter

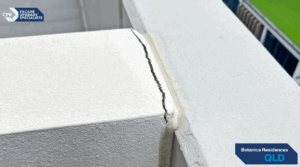

External waterproofing standards like AS4654.2 exist to ensure buildings are protected against Australia’s harsh climate—heavy rainfall, high humidity, and UV exposure. Non-compliance can lead to water ingress, mould, corrosion of steel reinforcement, concrete spalling, and costly remediation.

Benefits of AS4654.2 Compliance

- Durability: Extends the lifespan of external waterproofing systems.

- Safety: Prevents hazards caused by water penetration and structural weakening.

- Value Protection: Maintains property values by reducing costly remedial repairs.

- Legal Assurance: Meets building waterproofing regulations and avoids potential litigation.

- Peace of Mind: Offers strata committees and building managers confidence in long-term performance.

Scope of AS4654.2

AS4654.2 focuses on external above-ground waterproofing, covering elements such as roof decks, balconies, podiums, terraces, facade junctions, planter boxes, and external walls. It provides detailed construction waterproofing guidelines, from design through to installation, ensuring compliance with Australian waterproofing standards.

Key Components of Waterproofing Compliance AS4654.2

1. Waterproofing Membranes AS4654.2

The standard requires membranes that can withstand UV exposure, thermal movement, ponding water, and mechanical stress. High-performance membranes are essential for achieving long-lasting waterproofing protection.

2. Substrate Preparation

Surfaces must be structurally sound, clean, and dry. Defects in substrates compromise waterproofing performance and durability.

3. Detailing and Terminations

Critical junctions—such as wall-floor junctions, balcony edges, and penetrations—must be carefully detailed to prevent failure points.

4. Drainage and Falls

AS4654.2 mandates adequate falls to ensure water is directed away from surfaces, preventing ponding and structural stress.

5. Testing and Quality Assurance

Compliant projects often include water testing, inspection, and verification against an AS4654.2 compliance checklist.

Common Causes of External Waterproofing Failure

- Incorrect installation of waterproofing systems

- Use of non-compliant materials

- Poor substrate preparation

- Lack of drainage design

- Absence of ongoing maintenance

By adhering to AS4654.2, stakeholders can prevent these failures and secure long-term durability.

External Waterproofing Systems and Solutions

There is no one-size-fits-all solution. Choosing the right system depends on the application and performance requirements. Options include liquid-applied membranes, which are seamless and flexible; sheet membranes, which are pre-formed and resistant to puncture; and cementitious systems, which are durable and cost-effective for structural protection. Each system must meet the performance requirements outlined in AS4654.2.

Waterproofing Best Practices for Long-Term Protection

- Always follow construction waterproofing guidelines under AS4654.2.

- Select waterproofing membranes tested for UV, flexibility, and elongation.

- Ensure installers are qualified and experienced in external waterproofing standards.

- Integrate quality assurance systems to document compliance.

- Incorporate proactive maintenance schedules to maximise durability.

AS4654.2 Compliance Checklist

A simplified checklist includes:

- Membrane selection tested to AS4654.2

- Substrate inspection and preparation

- Detailing of terminations and junctions

- Drainage design meeting performance requirements

- On-site inspections and water testing

Following this ensures that building waterproofing regulations are consistently met.

The Role of CPR Facade Upgrades

At CPR Facade Upgrades, we specialise in Scaffold-Free™ waterproofing and facade remediation solutions for high-rise and difficult-access buildings. Our expertise in external waterproofing standards and our proprietary systems—including SkyPod®, PEARS®, and MARS™—allow us to deliver:

- Non-intrusive installation with no scaffolding and minimal disruption

- Certified compliance aligned with AS4654.2 waterproofing requirements

- Durable solutions tailored to each building

- Quality assurance through our SFS360® and SE2EPC® systems, which provide photographic records and traceable compliance for every project

For strata committees, building managers, and government asset custodians, CPR ensures waterproofing compliance with AS4654.2 is not just achieved but sustained for decades.

Conclusion

AS4654.2 external waterproofing standards are essential for protecting buildings against water damage, structural failure, and unnecessary remediation costs. By following the guidelines, selecting compliant systems, and working with experts like CPR Facade Upgrades, stakeholders can achieve long-lasting protection and peace of mind.

For tailored waterproofing solutions aligned with AS4654.2, explore our specialist services here: CPR Facade Waterproofing & Water Tightness