Understanding the Best Building Paint for Sealing in Australia

Choosing the best building paint for sealing in Australia isn’t just a technical decision. For strata committees, it’s about avoiding unexpected levies and long-term water damage. For building managers and consultants, it’s about safety, compliance, and selecting a paint system that genuinely performs in Australia’s harsh climate. And for residents, it’s about keeping their homes dry, protected, and visually appealing.

This guide breaks down the best sealing paint in Australia, from waterproof building paints to masonry sealing paints, exterior sealant systems, and moisture‑protection coatings suitable for commercial and high‑rise environments. We also explain why CPR’s Scaffold-Free™ access and AIMMS™ diagnostic system provide a smarter, more transparent way to determine exactly which sealing system your building needs—which means for you fewer surprises, fewer disruptions, and long-term protection backed by data.

What Is the Best Building Paint for Sealing in Australia? (Full Guide)

To answer this, we must consider Australia’s unique climate challenges:

- Intense UV

- High humidity in coastal cities

- Salt‑laden winds

- Heavy rain and wind‑driven moisture

- Expansive thermal movement in concrete and masonry

Because of these conditions, the best building paint for sealing in Australia is not a single product, but a performance‑engineered coating system designed to resist UV, moisture, cracking, and pollution—while maintaining flexibility and breathability.

Why Strata Committees Care About Sealing Paint

In CPR’s experience, strata committees often face:

- Fear of financial blowouts

- Pressure from residents to solve leaks fast

- Uncertainty about which contractor to trust

- Limited technical understanding of coating systems

This leads to delays, stress, and sometimes costly mistakes.

Our role is to simplify this decision with AIMMS™—our building diagnostic system that eliminates guesswork. AIMMS™ maps every defect and moisture path, which means for you a precise sealing specification built on evidence, not opinions.

What Makes a Building Paint Good for Sealing?

1. Waterproofing Performance

True sealing paints protect against:

- Wind‑driven rain

- Capillary moisture penetration

- Micro‑cracks letting water in

- Damp issues from balconies or parapets

Waterproof building paint is essential for tall and coastal buildings.

2. Flexibility & Crack Bridging

Australia’s temperature swings cause expansion and contraction. A good sealing paint must move with the substrate.

3. UV Resistance

The sun is Australia’s biggest paint‑destroyer. UV‑resistant paint prevents:

- Fading

- Chalking

- Film breakdown

- Early repaint cycles

4. Breathability

The best sealing paints stop external moisture—but allow internal vapour to escape.

5. Adhesion Strength

For multi‑decade performance, the coating must bond strongly to:

- Concrete

- Render

- Masonry

- Fibre cement

- Previously painted surfaces

6. Mould & Algae Resistance

Humidity zones (e.g., NSW North Coast, Queensland) need mould‑resistant binders and additives.

7. System Compatibility

A sealing system typically includes:

- Primer

- Membrane or elastomeric layer

- Topcoat

AIMMS™ identifies exactly which layers are required for each building zone.

Reviewing the Best Types of Building Sealing Paint in Australia

Below is a detailed review of the most effective sealing systems.

1. Acrylic Elastomeric Coatings (Best All‑Round Sealing Solution)

Why they’re chosen for high‑rise buildings:

- Excellent elasticity

- Waterproof and breathable

- Highly UV‑resistant

- Cost‑effective for commercial and strata buildings

- Strong adhesion to concrete and render

This is considered the best building paint for sealing in Australia for most situations.

2. Rubber Paint for Buildings (High Crack Movement)

Rubberised coatings provide:

- Extreme stretch

- Strong moisture block

- Durable exterior sealing

Used in areas needing significant flexibility.

3. Masonry Sealing Paint

Ideal for:

- Brick

- Blockwork

- Cement render

Provides deep substrate penetration and long‑lasting moisture protection.

4. Concrete Sealant Paint

Used where moisture intrusion through concrete is a concern.

Provides:

- Waterproofing

- Dust control

- Improved film strength

5. Siloxane/Silicone‑Enhanced Sealers

Best for:

- High rainfall regions

- Coastal buildings

- Salt‑exposed façades

Highly hydrophobic and UV‑resistant.

6. Weatherproof Paint for Australia

Weatherproofing coatings are engineered to protect against:

- Rain

- Salt spray

- High winds

- UV breakdown

A good system must combine weatherproof paint with elastomeric membranes.

7. Commercial Sealing Paint (Heavy‑Duty Coatings)

Used on:

- Shopping centres

- Industrial buildings

- Government assets

- Large strata complexes

Engineered to withstand heavy moisture cycles and environmental stresses.

So, What Is the Best Building Paint for Sealing in Australia?

The most reliable answer is:

A high‑performance elastomeric acrylic sealing system, reinforced with primers, membranes, and a UV‑resistant finish coat—specified using AIMMS™ data.

A single tin of paint is never the solution.

A sealing system is.

This approach ensures:

- Waterproofing

- Breathability

- UV resistance

- Crack bridging

- Long‑term durability

And because CPR uses Scaffold-Free™ access systems—MARS™, PEARS®, and SkyPod®—we deliver sealing and protective coating projects with up to 30% cost savings, less noise, and minimal resident disruption.

Why AIMMS™ Is Essential When Choosing a Sealing Paint System

Traditional building inspections miss hidden moisture pathways.

AIMMS™ solves this with:

- High‑resolution façade mapping

- Drop‑by‑drop analysis

- Transparent defect records

- Precise coating recommendations

Which means for you:

- No inflated scopes

- Transparent diagnosis

- Permanent digital documentation

- Confidence that you’re only paying for what the building actually needs

Strata committees value this because it provides peace of mind.

Building managers value it because it reduces resident complaints.

Consultants value it because it provides technical certainty.

Scaffold-Free™ Access Makes Sealing More Affordable

Most sealing projects become expensive due to scaffolding.

CPR’s patented Scaffold-Free™ access replaces scaffolding, offering:

- Faster project delivery (e.g., 3 months instead of 6)

- Lower costs

- Less noise

- No privacy invasion

- Safer operations at height

Which means for you:

- Significant cost savings

- Fewer disruptions

- A quieter, cleaner sealing project

How to Choose the Right Sealing Paint for Your Building

Step 1: AIMMS™ Inspection

Data‑based assessment of:

- Moisture mapping

- Crack identification

- Film adhesion issues

- Substrate breakdown

Step 2: Sealing Specification

We determine:

- Primer type

- Membrane thickness

- Coating flexibility class

- UV topcoat

Step 3: Scaffold-Free™ Application

SkyPod® workstations ensure safe, precise work with minimal disruption.

Step 4: Quality Assurance

AIMMS™ records photographic evidence of every stage.

Step 5: AssetCare™ Maintenance

Ensures long‑term performance.

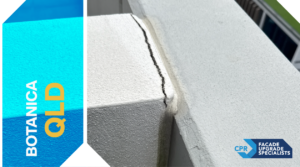

Common Moisture Issues Sealing Paint Can Solve

- Leaking balconies

- Hairline cracking

- Damp interior walls

- Façade spalling

- Mould growth

- Paint blistering

- Salt‑damage on coastal buildings

With the right sealing system, these issues can be prevented for decades.

Why CPR Is Trusted for Sealing and Protective Coatings

Strata committees, managers, and consultants choose CPR because:

- We provide Scaffold-Free™ cost savings

- AIMMS™ ensures transparency

- Our Accredited Service Partners™ are trained to the highest standard

- We deliver multi‑decade protective solutions

- We offer AssetCare™ for long‑term preservation

- Our video testimonials prove consistent success

Protect Your Building with the Right Sealing System

See how AIMMS™ and Scaffold-Free™ innovations can protect your building for decades.