Ensuring compliance with AS 3740 in wet area construction is not only a regulatory requirement but also a cornerstone of protecting buildings against water damage and costly remediation. This Australian waterproofing standard outlines the minimum requirements for the design and installation of waterproofing in domestic wet areas such as bathrooms, laundries, and kitchens. Following best practices in line with AS 3740 compliance guarantees the safety, durability, and functionality of a property’s wet areas while also reducing the risk of disputes, rectification costs, and insurance claims.

In this article, we will explore the essentials of AS 3740 waterproofing, highlight common mistakes, and provide a practical guide to ensuring compliance through design, construction, inspection, and long-term maintenance.

Understanding AS 3740 and Its Role in Wet Area Construction

AS 3740 waterproofing sets the benchmark for domestic wet area waterproofing. It provides clear requirements for the extent of waterproofing in bathrooms, laundries, and toilets, materials and installation methods for membranes and sealants, shower waterproofing requirements and floor grading, and junction treatments where walls, floors, and penetrations meet.

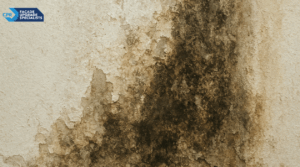

The goal is simple: prevent water ingress that could lead to deterioration, mould growth, and structural issues. By following Australian waterproofing standards, builders and contractors ensure the integrity of wet area construction while protecting occupants from health and safety risks.

Key Areas Covered by AS 3740 Guidelines

Shower Areas

Entire floors within shower recesses must be waterproofed. Walls must be waterproofed to a minimum of 150mm above the shower floor, and to 1800mm where showerheads are attached.

Baths and Spa Baths

The junctions between baths, walls, and floors must be waterproofed. Steps and surrounds should comply with bathroom waterproofing AS 3740 standards.

Laundries and Toilets

All floor wastes must be waterproofed with adequate membrane coverage. Wall junctions up to 150mm should be sealed.

Penetrations and Fixtures

Pipes, wastes, and other penetrations must be sealed with appropriate collars or grommets. Skirting tiles must be fully covered by the waterproofing system.

Best Practices for AS 3740 Compliance

Integrate Waterproofing at the Design Stage

Early planning ensures that wet area design and construction allow for correct falls, drainage, and membrane installation. Including a waterproofing compliance checklist in the design documentation minimises the risk of oversight during construction.

Select the Right Materials

Only use products tested and certified to meet Australian waterproofing standards. Membranes should be flexible, durable, and compatible with substrates and adhesives. Always follow manufacturer instructions and AS 3740 guidelines.

Employ Qualified Installers

Waterproofing is a licensed trade in most Australian states. Ensuring installers are trained in AS 3740 compliance reduces risks of poor workmanship and provides legal protection in case of disputes.

Ensure Adequate Surface Preparation

Surfaces must be clean, dry, and free of contaminants. Inadequate preparation is one of the most common waterproofing mistakes leading to system failure.

Overlap and Reinforce Junctions

Corners, wall-floor junctions, and penetrations are high-risk areas. Reinforcement with bond-breaker tapes or pre-formed corners ensures compliance and durability.

Conduct Thorough Inspections

Implementing waterproofing inspection standards is vital. Builders and supervisors should verify that membranes meet thickness requirements, are applied continuously, and cover all necessary areas before tiling commences.

Document and Certify Work

Detailed photographic records, compliance certificates, and warranties protect both contractors and clients. This documentation also simplifies future maintenance and insurance claims.

Common Waterproofing Mistakes to Avoid

Even with clear AS 3740 guidelines, errors can occur. Some of the most frequent include using unapproved or incompatible products, inadequate curing time before tiling, failing to waterproof behind fixtures such as vanities or bathtubs, incorrect floor grading leading to water pooling, and skipping reinforcement at vulnerable junctions. Avoiding these mistakes not only ensures wet area construction standards are met but also saves thousands in potential rectification costs.

Preventing Water Damage in Homes

Waterproofing done correctly at the construction phase reduces long-term maintenance issues. Key prevention strategies include designing wet areas with proper falls to drains, routine inspections to detect minor leaks early, immediate repair of cracked tiles, grout, or sealants, and engaging in bathroom waterproofing best practices for both new builds and renovations.

Long-Term Compliance and Maintenance

AS 3740 compliance doesn’t end at installation. Ongoing maintenance ensures the system’s effectiveness over time. Regularly inspect seals around showers, baths, and sinks. Replace degraded silicone or grout promptly. Use non-abrasive cleaners to avoid damaging membranes. Keep compliance certificates and inspection records for future reference.

By adopting a proactive approach, homeowners and managers can extend the lifespan of wet areas while ensuring waterproofing regulations in Australia are consistently met.

Why Compliance with AS 3740 Matters

Non-compliance can result in costly rectification works, insurance claim rejections, health risks from mould and damp, and structural damage to walls, floors, and adjoining areas. By following bathroom waterproofing AS 3740 and other relevant standards, builders and property owners safeguard both their investment and occupant wellbeing.

Partnering with Experts in Waterproofing and Preservation

At CPR, we specialise in waterproofing and water tightness solutions for high-rise, strata, government, and commercial buildings. Using our Scaffold-Free™ systems such as SkyPod®, PEARS®, and MARS™, we deliver precise, unobtrusive, and fully compliant waterproofing and remediation solutions for even the most difficult-to-access structures.

Our SFS360® (Sky Facade Scope 360) and SE2EPC® (Sky End 2 End Project Care) quality assurance systems provide photographic evidence, compliance tracking, and long-term preservation strategies that ensure AS 3740 compliance is met and maintained.

If you are seeking reliable expertise to meet AS 3740 guidelines while protecting your property from water ingress, our team is here to help.

Discover our Waterproofing & Water Tightness Solutions

Explore our Full Preservation Services

Conclusion

Compliance with AS 3740 in wet area construction is a non-negotiable aspect of building design and execution. By adopting industry best practices, employing qualified professionals, and integrating long-term maintenance strategies, builders and property owners can avoid costly issues while ensuring safety, durability, and peace of mind.