How to fill cement cracks is one of the most common questions strata committees and building managers ask when cracks start appearing in concrete facades, slabs, balconies, or podiums. And it’s a fair question — cracks look simple, but getting them wrong can lead to water ingress, corrosion, safety risks, and major cost blowouts down the track.

If you’re responsible for a strata or high‑rise building, this guide will help you understand how to fill cement cracks properly, when DIY concrete crack repair is acceptable, and when professional, data‑driven remediation is the smarter long‑term decision.

We’ll explain the causes of cracks, the right cement crack filler for each situation, and how CPR’s Scaffold‑Free™ systems and AIMMS™ methodology deliver multi‑decade concrete crack repair with minimal disruption.

Why cement cracks appear in buildings

Cracks in cement and concrete are not random. They are symptoms of movement, stress, or material breakdown. Understanding why they appear is essential before you attempt to fill cracks in concrete.

Common causes include:

- Thermal expansion and contraction

- Building settlement and structural movement

- Water ingress and moisture cycling

- Reinforcement corrosion

- Poor original workmanship or ageing materials

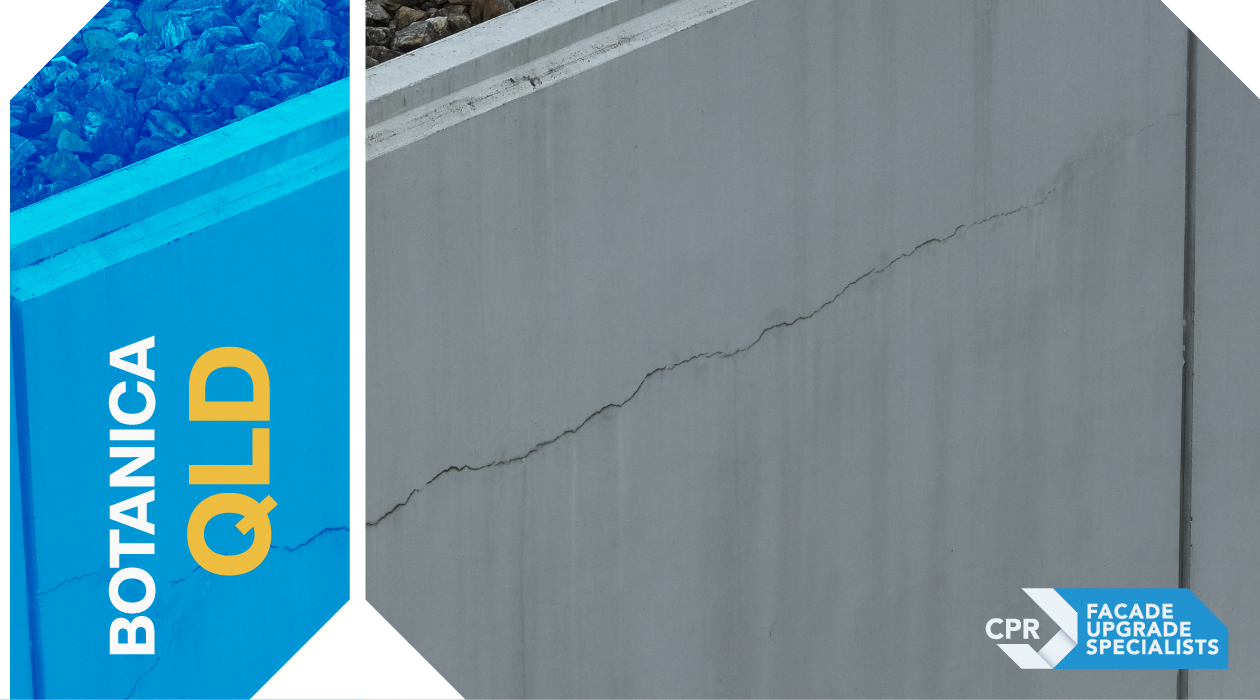

In high‑rise and strata buildings, cracks rarely exist in isolation. What looks like a small surface defect may connect to deeper structural or durability issues.

This is why CPR never starts with assumptions. We start with AIMMS™, our inspection and documentation system, which maps every defect precisely — which means for you no guesswork, no hidden scope, and no unexpected extras later.

Types of cement cracks you need to identify first

Before choosing a concrete crack filler, you must identify the crack type. Different cracks require different repair methods.

Hairline cracks

- Very thin surface cracks

- Often caused by shrinkage or minor thermal movement

- Common on slabs and rendered surfaces

These can sometimes be addressed with surface‑level cement crack filler, but only if movement has stopped.

Structural cracks

- Wider, deeper, or stepped cracks

- Often linked to load movement or substrate failure

- High risk if ignored

Structural cracks require professional concrete crack repair, not DIY solutions.

Active vs dormant cracks

- Active cracks continue to move

- Dormant cracks have stabilised

Filling an active crack without accommodating movement almost guarantees failure.

How to fill cement cracks: step‑by‑step fundamentals

At a basic level, the process of how to fill cement cracks follows these principles:

- Clean the crack thoroughly – remove dust, debris, salts, and loose material

- Prepare the crack profile – sometimes widening is required for proper bonding

- Select the correct concrete crack filler – based on crack type and movement

- Apply and cure correctly – rushed curing leads to early failure

- Seal and protect – especially on external facades

Skipping any of these steps compromises the repair.

Choosing the right cement crack filler

There is no single “best concrete crack repair product” for all situations. The correct material depends on movement, exposure, and structural role.

Common concrete crack filler types

- Cementitious repair mortars

- Epoxy injection systems

- Flexible polyurethane sealants

- Polymer‑modified patching compounds

For example:

- Rigid epoxy may restore structural continuity — which means for you improved load transfer and durability

- Flexible sealants accommodate movement — which means for you reduced risk of crack re‑opening

Using the wrong product is one of the most common causes of premature repair failure.

Fix cracks in concrete floor vs external facades

Cement floor crack repair

Internal slabs and floors often allow more straightforward repair:

- Minimal weather exposure

- Easier access

- Lower safety risk

DIY concrete crack repair may be acceptable for non‑structural floor cracks in low‑risk areas.

External and facade concrete crack repair

External cracks are a different story:

- Constant weather exposure

- Water ingress risk

- Falling debris hazards

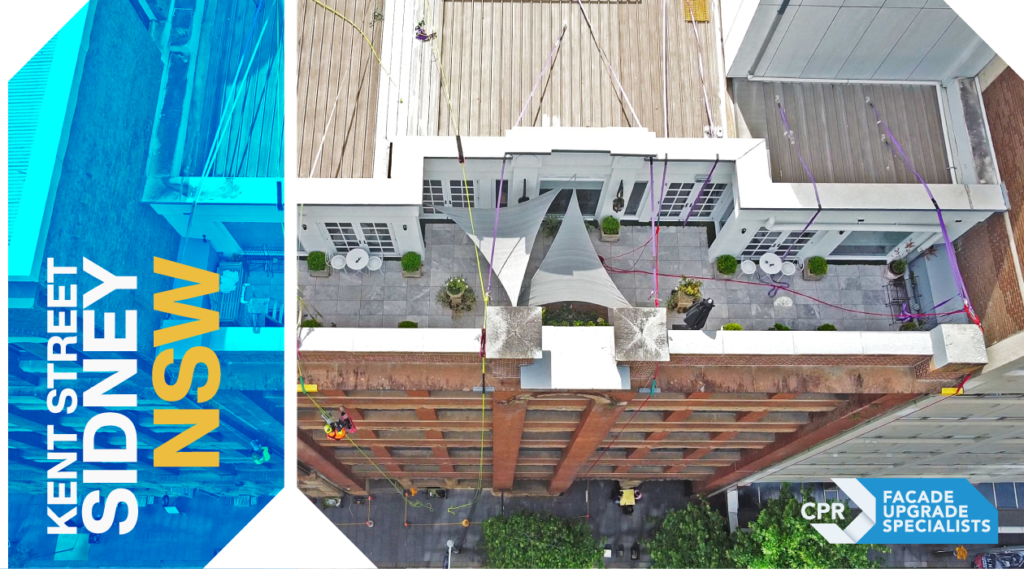

- Difficult access

This is where CPR’s Scaffold‑Free™ access systems (MARS™, PEARS®, SkyPod®) become critical — which means for you safer works, faster completion, and cost savings of up to 30% compared to scaffolding.

Why DIY concrete crack repair often fails on strata buildings

DIY concrete crack repair is heavily marketed, but rarely suitable for strata or high‑rise assets.

Common DIY failures include:

- Treating symptoms, not root causes

- Using incompatible materials

- Ignoring ongoing movement

- No long‑term performance data

When DIY repairs fail, the cost of remediation is often higher than doing it properly the first time.

Concrete crack sealing and water ingress prevention

Water is the silent destroyer of concrete.

Even small cracks allow moisture to reach reinforcement steel, triggering corrosion and concrete spalling.

Concrete crack sealing is therefore not cosmetic — it is a durability strategy.

CPR integrates crack repair with water ingress control under AIMMS™, ensuring:

- Defects are mapped and prioritised

- Repairs are sequenced correctly

- Long‑term asset performance is protected

Which means for you fewer repeat repairs and predictable maintenance planning.

How to patch cement cracks the professional way

Professional cement crack repair follows a system, not guesswork.

CPR’s process includes:

- Close‑range inspection using AIMMS™

- Defect classification and severity grading

- Material selection based on exposure and movement

- Controlled application using SkyPod® workstations

- Before‑and‑after photographic records

This transparency protects strata committees from disputes and unexpected scope creep.

Cost considerations: short‑term fixes vs long‑term value

It’s natural to worry about budgets.

However, repeated short‑term crack repairs often cost more than one properly engineered solution.

CPR focuses on:

- Multi‑decade repair performance

- Reduced lifecycle costs

- Minimal disruption to residents

Which means for you better value, not just lower upfront pricing.

Safety, access, and compliance in concrete crack repair

Working at height introduces real risk.

Traditional scaffolding:

- Increases cost

- Increases disruption

- Increases project duration

CPR’s Scaffold‑Free™ systems allow technicians to work externally, quietly, and safely — which means for you improved safety outcomes and faster project delivery.

When filling cement cracks becomes facade remediation

Cracks are often early warning signs.

If multiple cracks appear across elevations, balconies, or structural elements, the issue is no longer “how to fill cement cracks” — it becomes facade remediation.

This is where CPR’s consultancy‑led approach protects strata committees from reactive spending.

Proof, not promises

CPR backs every recommendation with:

- Award‑winning remediation projects

- Independent case studies

- Video testimonials from strata committees

- Documented before‑and‑after evidence via AIMMS™

Trust is built on proof.

The smarter next step

If you’re unsure whether your building needs a simple crack repair or a strategic remediation plan, the safest move is clarity.

Book a professional consultation, request an AIMMS™ demo, or explore CPR’s concrete repair solutions to understand the true condition of your asset.