How to repair cracks in concrete? It’s one of the most common — and most misunderstood — questions strata committees, building managers, and consultants face when maintaining ageing buildings.

Within the first signs of cracking, many people worry about cost blowouts, ongoing disruption, or whether they’re about to uncover a much bigger structural problem. Those concerns are valid. Concrete cracking can range from harmless surface wear to early warnings of long‑term durability failure — and knowing the difference is what protects both budgets and buildings.

This guide explains how to repair cracks in concrete properly, with a focus on strata and high‑rise buildings in Australia. We’ll walk through concrete crack repair methods, when DIY concrete crack repair is appropriate, and when professional remediation is essential. We’ll also explain how CPR’s Scaffold‑Free™ approach and AIMMS™ system remove guesswork, reduce disruption, and deliver multi‑decade results.

Understanding Why Concrete Cracks in the First Place

Concrete is strong — but it isn’t flexible. Over time, environmental stress, movement, moisture, and corrosion work together to create cracks. The key is understanding why a crack has formed before deciding how to repair it.

Common Causes of Concrete Cracking in Buildings

- Thermal movement from daily and seasonal temperature changes

- Shrinkage during curing, especially in older construction

- Moisture ingress, leading to expansion and internal pressure

- Steel reinforcement corrosion, often called concrete cancer

- Structural movement or settlement

- Poor original detailing or workmanship

Each cause requires a different concrete crack repair approach. Treating the symptom without addressing the cause often leads to repeat repairs — which means higher long‑term costs for owners.

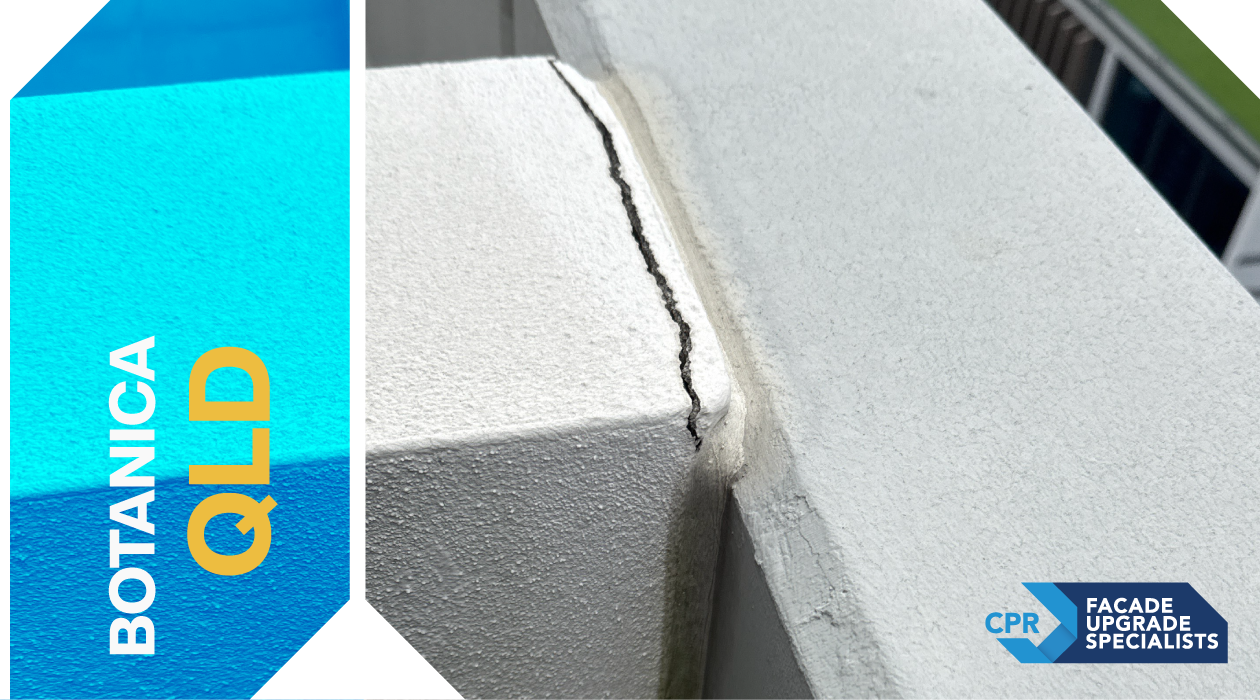

Types of Cracks and Why Classification Matters

Not all cracks are equal. Correct classification determines the safest and most cost‑effective repair strategy.

Hairline Cracks in Concrete Repair

Hairline cracks are narrow, shallow, and often cosmetic. They typically appear in rendered finishes, balcony edges, or exposed slabs.

While these cracks may seem minor, they can allow water ingress over time — which means corrosion risk if left untreated.

Typical solutions include:

- Flexible concrete crack sealant

- Surface concrete crack filler

- Protective coating systems

Deep Cracks in Concrete Repair

Deep cracks extend through the concrete and may expose reinforcement steel. These cracks often indicate active corrosion or structural stress.

Deep cracks require more than surface filling. Without proper treatment, they can compromise structural durability.

Typical solutions include:

- Concrete breakout and steel treatment

- Structural concrete crack repair methods

- Reprofiling with engineered repair mortars

How to Repair Cracks in Concrete: Step‑by‑Step Framework

Understanding how to repair cracks in concrete starts with a structured process — not a product choice.

Step 1: Diagnose Before You Repair

Effective concrete crack repair begins with inspection. CPR uses AIMMS™, our proprietary assessment and documentation system, which means for you:

- Every crack is mapped, measured, and classified

- Root causes are identified, not guessed

- Scope and costs are defined upfront

This removes uncertainty and prevents unnecessary repairs.

Step 2: Select the Right Concrete Crack Repair Method

Different cracks require different solutions. Common concrete crack repair methods include:

- Flexible sealants for moving or hairline cracks

- Epoxy injection for structural bonding

- Polymer‑modified repair mortars for concrete surface repair

- Corrosion treatment systems for reinforced concrete

Choosing the wrong method may look cheaper initially — but often leads to failure within a few years.

Step 3: Prepare the Substrate Properly

Preparation is where most DIY concrete crack repair attempts fail.

Proper preparation includes:

- Controlled breakout of damaged concrete

- Cleaning and treating reinforcement steel

- Removing salts, contaminants, and moisture

CPR’s SkyPod® workstations allow this work to be completed externally, which means for you:

- No scaffolding

- No apartment access

- Minimal noise and disruption

Step 4: Apply Repair and Protective Systems

Repairs are completed using engineered materials suited to exposure conditions, followed by protective coatings designed to prevent future cracking.

This is where long‑term value is created — not just visual improvement.

Best Concrete Crack Repair Products — And When Products Aren’t Enough

Search results often focus on the best concrete crack repair products. While products matter, systems matter more.

Where DIY Concrete Crack Repair Can Work

DIY concrete crack repair may be suitable for:

- Small, non‑structural hairline cracks

- Low‑risk areas like garden paths or minor slab edges

Even then, DIY solutions should be monitored regularly.

Why DIY Fails in Strata and High‑Rise Buildings

For multi‑storey buildings, DIY concrete crack repair is rarely appropriate because:

- Access is unsafe

- Root causes aren’t addressed

- Liability and safety risks increase

Professional remediation ensures compliance, durability, and peace of mind.

Repairing Cracked Concrete Driveways vs Building Facades

Many guides focus on repairing cracked concrete driveways. Facade repairs are very different.

Key differences include:

- Vertical load behaviour

- Weather exposure

- Safety and access complexity

- Compliance requirements

Facade concrete repairs must meet stricter durability and safety standards — which is why CPR specialises exclusively in difficult‑access structures.

How to Seal Cracks in Concrete for Long‑Term Protection

Sealing is not just about closing a gap. It’s about preventing future damage.

Effective concrete crack sealant systems:

- Accommodate movement

- Resist UV and moisture

- Integrate with facade coatings

CPR integrates sealing into broader concrete maintenance and repair programs, supported by AssetCare™, which means for you:

- Ongoing monitoring

- Reduced future repair costs

- Extended facade lifespan

Prevent Cracks in Concrete Before They Become Expensive

Prevention is always more affordable than reactive repair.

Proactive Concrete Maintenance and Repair Strategies

- Regular facade inspections

- Early treatment of hairline cracks

- Moisture management

- Protective coating renewal cycles

Through AIMMS™, CPR provides transparent records and condition tracking — which means strata committees can plan budgets confidently instead of reacting to emergencies.

Why Scaffold‑Free™ Concrete Repair Changes the Economics

Traditional concrete repair relies on scaffolding — often accounting for up to 30% of project costs.

CPR’s Scaffold‑Free™ access using MARS™, PEARS®, and SkyPod® eliminates that overhead, which means for you:

- Significant cost savings

- Faster project timelines

- Minimal disruption to residents and businesses

These systems are award‑recognised and proven across hundreds of Australian projects.

Trust, Transparency, and Proof — Not Promises

CPR backs every concrete crack repair with:

- Documented inspections via AIMMS™

- Before‑and‑after photographic records

- Accredited Service Partners™

- Case studies and video testimonials

This transparency builds trust — especially important for strata committees responsible for shared funds.

When to Seek Professional Concrete Crack Repair Advice

If cracks are:

- Widening

- Rust‑stained

- Reappearing after repair

- Associated with leaks or spalling

…it’s time for professional assessment.

Book a concrete repair consultation or request an AIMMS™ demonstration.

Final Thoughts: Repair Once. Repair Properly.

Knowing how to repair cracks in concrete is about more than filling gaps. It’s about understanding risk, protecting value, and choosing solutions that last decades — not years.

With CPR’s Scaffold‑Free™ technology, data‑driven AIMMS™ system, and AssetCare™ maintenance, concrete crack repair becomes predictable, transparent, and cost‑effective.