Epoxy concrete repair for high‑rise buildings is one of the most trusted, long‑lasting ways to restore structural integrity, stop water ingress, and extend a building’s lifespan. For strata committees, epoxy repairs often feel confusing, technical, and expensive—and many worry about hidden costs or disruptive works. For building managers and consultants, accuracy, safety, and reliability are key.

At CPR Facade Upgrades, we understand these concerns deeply. Our role is to simplify the process and provide certainty through data, transparency, and highly efficient Scaffold‑Free™ access using MARS™, PEARS®, and SkyPod® systems. Combined with our AIMMS™ inspection and documentation platform, epoxy concrete repair becomes not just a fix, but a multi‑decade solution delivered with minimal disruption.

What Is the Epoxy Concrete Repair for High‑Rise Buildings?

Epoxy concrete repair for high‑rise buildings refers to the use of high‑strength epoxy resins to restore damaged structural concrete, seal cracks, bond delaminated surfaces, and reinforce load‑bearing elements. The method is widely used for structural concrete epoxy, concrete crack repair epoxy, and epoxy injection for structural cracks—particularly in towers, complexes, and difficult‑to‑access facades.

Because high‑rise buildings experience constant wind load, movement, weather exposure, and hydrostatic pressure, epoxy repair offers a durable, flexible, and stable solution that strengthens the concrete matrix itself.

But the real challenge isn’t the epoxy. It’s safe access, transparency, and preventing cost blowouts.

This is where CPR’s Scaffold‑Free™ methodology and AIMMS™ set a new standard.

Why Epoxy Concrete Repair Matters for High‑Rise Buildings

Epoxy repair is essential for maintaining structural integrity and preventing long‑term deterioration. Over time, concrete in high‑rise buildings can crack, delaminate, or spall due to:

- Water ingress

- Reinforcement corrosion

- Movement and vibration

- Temperature fluctuations

- Ageing and carbonation

- Poor workmanship in original construction

Trusted Neighbour Tone (for strata committees)

We know how stressful it is when you start seeing cracks or falling concrete. Most owners immediately worry: “How much will this cost us?” or “Will we need scaffolding around our building for months?” Epoxy repair helps you fix the issue once—without the recurring headaches or unnecessary expenses.

Confident Innovator Tone (for managers & consultants)

Epoxy systems deliver superior adhesion, compressive strength, and structural reinforcement. When applied following precise substrate preparation and injection pressures, epoxy restores the original monolithic characteristics of concrete—ensuring long‑term performance and predictable outcomes.

How Epoxy Is Used in Concrete Repair (Step‑by‑Step)

Every epoxy concrete repair follows a systematic process to ensure the resin penetrates deeply and bonds permanently.

1. AIMMS™ Data‑Driven Inspection

Before any epoxy is applied, CPR conducts a detailed AIMMS™ assessment. This creates a visual digital record of every defect, including:

- Crack width, depth, and location

- Spalling and delamination zones

- Moisture‑affected areas

- Concrete movement patterns

AIMMS™ removes guesswork entirely—which means for you, decisions are based on evidence, not assumptions.

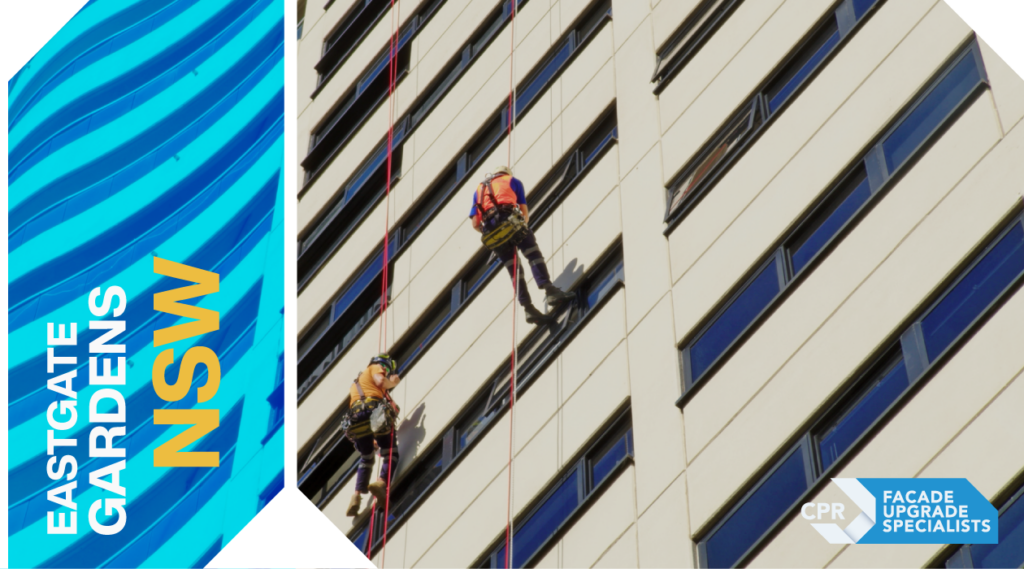

2. Safe Scaffold‑Free™ Access

Our patented MARS™, PEARS®, and SkyPod® systems allow our team to reach every façade zone safely, quietly, and unobtrusively. This:

- Reduces costs significantly by avoiding scaffolding

- Eliminates disruption for residents

- Speeds up project timelines

- Provides ergonomic and dust‑controlled work areas

Scaffold‑Free™ technology means for you: no privacy issues, no noisy construction zones, and no visual obstruction for months.

3. Surface Preparation

Concrete is cleaned, ground, and opened to allow epoxy to penetrate fully. This may include:

- Crack chasing

- Removal of weak or delaminated material

- Vacuum extraction using dust‑control SkyPod® systems

4. Epoxy Injection (Structural Cracks)

Low‑ to high‑pressure injection methods push epoxy deep into the concrete matrix. This:

- Restores structural capacity

- Bonds separated concrete elements

- Prevents moisture penetration

- Stops corrosion cycles

5. Epoxy Patching and Rebuilding

For non‑structural damage, high‑build epoxy mortars are applied to rebuild:

- Spalled concrete

- Edges and beams

- Balconies

- Columns and façade elements

6. Finishing and Long‑Term Protection

After repairs, surfaces may be:

- Reprofiled

- Recoated

- Waterproofed

Our AssetCare™ service ensures the repairs last for decades.

Benefits of Epoxy Concrete Repair for High‑Rise Buildings

Epoxy systems offer advantages unmatched by traditional cementitious repair products.

1. Structural Strength

Epoxy can exceed concrete’s compressive and tensile strength, making it ideal for reinforcing compromised areas.

2. Waterproofing and Durability

Epoxy creates a tight, waterproof bond that stops ongoing deterioration.

3. Cost Savings

When combined with CPR’s Scaffold‑Free™ methodology and AIMMS™ transparency, clients avoid:

- Scaffolding costs

- Extended project timelines

- Misdiagnosed scopes of work

- Unnecessary repairs

4. Non‑Disruptive Works

SkyPod® encapsulated workstations allow repairs to occur quietly and cleanly—with minimal impact on residents or neighbouring buildings.

5. Multi‑Decade Performance

Unlike patch repairs that fail within a few years, epoxy systems deliver decades of stability and reduced maintenance.

Epoxy vs Polyurethane Concrete Repair

Clients often ask about the difference.

Epoxy

- Structural strength

- Bonds cracked concrete

- Ideal for static cracks

- Long‑term loads bearing reinforcement

Polyurethane

- More flexible

- Used for active or moving cracks

- Best for leak sealing only

Epoxy is the superior choice for structural repairs, especially on high‑rise façades exposed to dynamic wind loads.

Best Epoxy Products for High‑Rise Concrete Repair

Our team uses only Australian‑standard approved epoxy systems suitable for:

- Structural crack injection

- High‑strength patching

- Reinforcement corrosion protection

- Carbon fibre reinforcement bonding

Each product is selected based on AIMMS™ data, ensuring cost efficiency and long‑term performance.

Common High‑Rise Concrete Problems Epoxy Repair Solves

1. Concrete cancer (spalling)

2. Corroded reinforcement

3. Water‑ingress cracking

4. Delamination from salt air

5. Balustrade and balcony failures

6. Beam and column cracking

7. Façade movement cracking

Cost of Epoxy Concrete Repair for High‑Rise Buildings

Epoxy concrete repair costs vary depending on:

- Crack width and depth

- Accessibility (solved by Scaffold‑Free™ methods)

- Quantity of repairs

- Complexity of patching

Most cost blowouts in the industry happen due to inaccurate quotes or poor inspection methods—issues eliminated by AIMMS™.

AIMMS™ gives strata committees certainty before spending, which means for you:

- No unexpected invoices

- Clear scope and cost

- Transparent photographic evidence

Why CPR Is the Safer, Smarter, More Affordable Choice

We remove the biggest cost driver—scaffolding.

With Scaffold‑Free™ access, buildings avoid six‑figure expenses instantly.

AIMMS™ creates certainty.

Strata committees gain a digital record of every defect and repair—permanent, traceable, undeniable.

SkyPod® workstations keep residents safe.

No falling debris. No noise. No privacy issues.

We deliver multi‑decade solutions, not quick fixes.

Concrete repairs last longer when done right.

Our team are Accredited Service Partners™.

Highly trained, rope‑access certified experts ensure every patch is carried out to specification.