WHAT IS PEARS™

Portable Elevator Access Rope System is an innovative powered device by CPR that

provides our tradesmen the advantage of doing more work with less effort in a

much safer manner.

provides our tradesmen the advantage of doing more work with less effort in a

much safer manner.

Overview

The use of PEARS™ in the building industry is a relatively new

development and has pioneered by the team at CPR technologies.

Its implementation provides key benefits including:

Its implementation provides key benefits including:

- Optimising levels of safety

- Reduction of fatigue

- Increase in productivity

- Quicker turnarounds

- Lower costs for end usersSuperior after care and cleaning.

Pears™ facilitates the operator to carry a lot more tools and other essential equipment such as SkyPods™ , SkyNet™ catching systems, vacuum and power tools that otherwise would be impossible to manage with traditional abseiling.

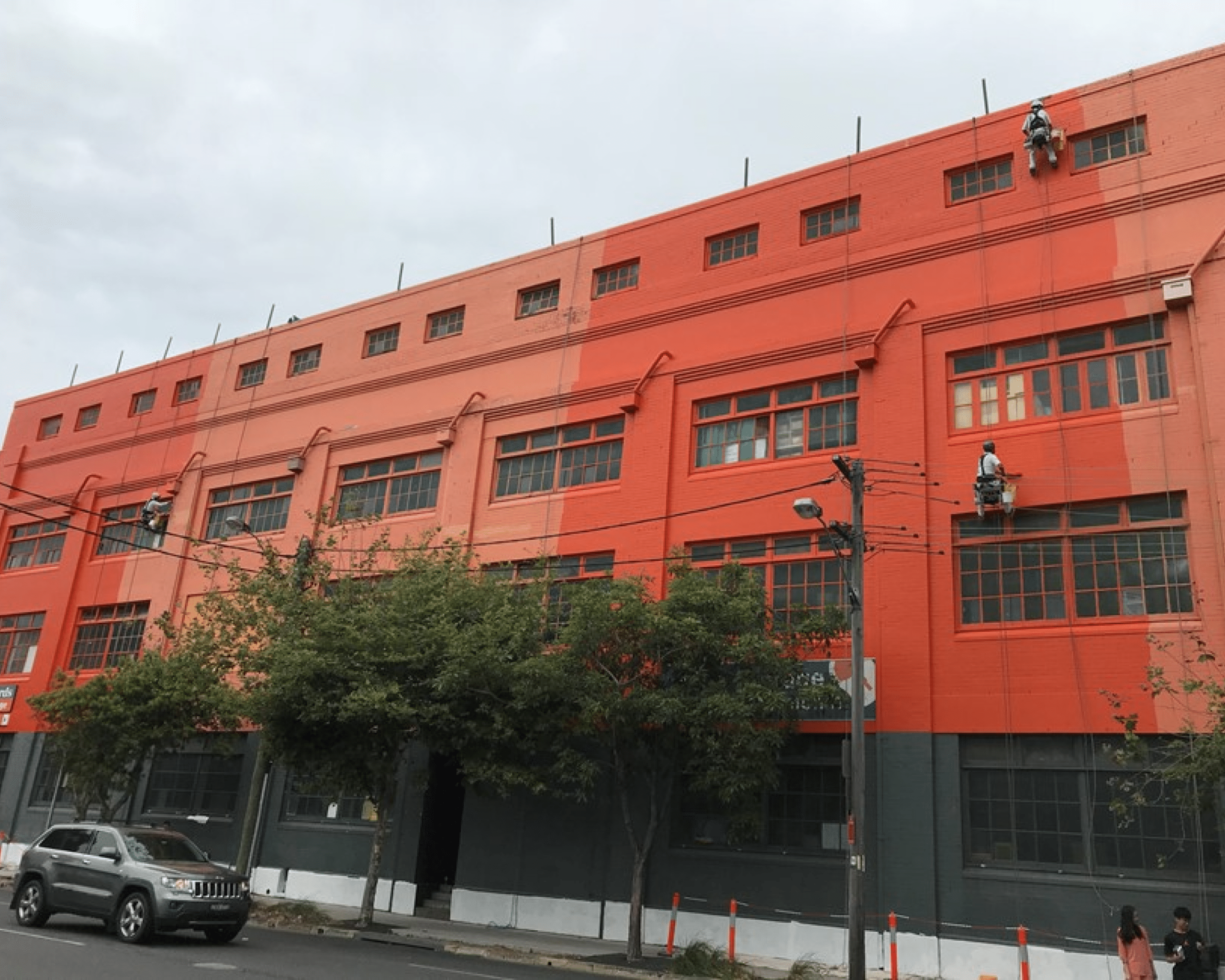

Case Study: Reduction of fatigue and huge cost savings with

comparison Of PEARSTM against conventional Abseiling rope access.

The case study below is a job we completed for Kennards Alexandria and helps us to outline the key benefits linked with CPR Pears™

Imagine a commercial building such as Kennards Self Storage Waterloo which was due for a repaint. The building manager wanted to use a rope access team as he

knew that it would cost a small fortune to erect scaffolding. The swing stage was not an option either as the roof is metal and in some sections is pitched.

knew that it would cost a small fortune to erect scaffolding. The swing stage was not an option either as the roof is metal and in some sections is pitched.

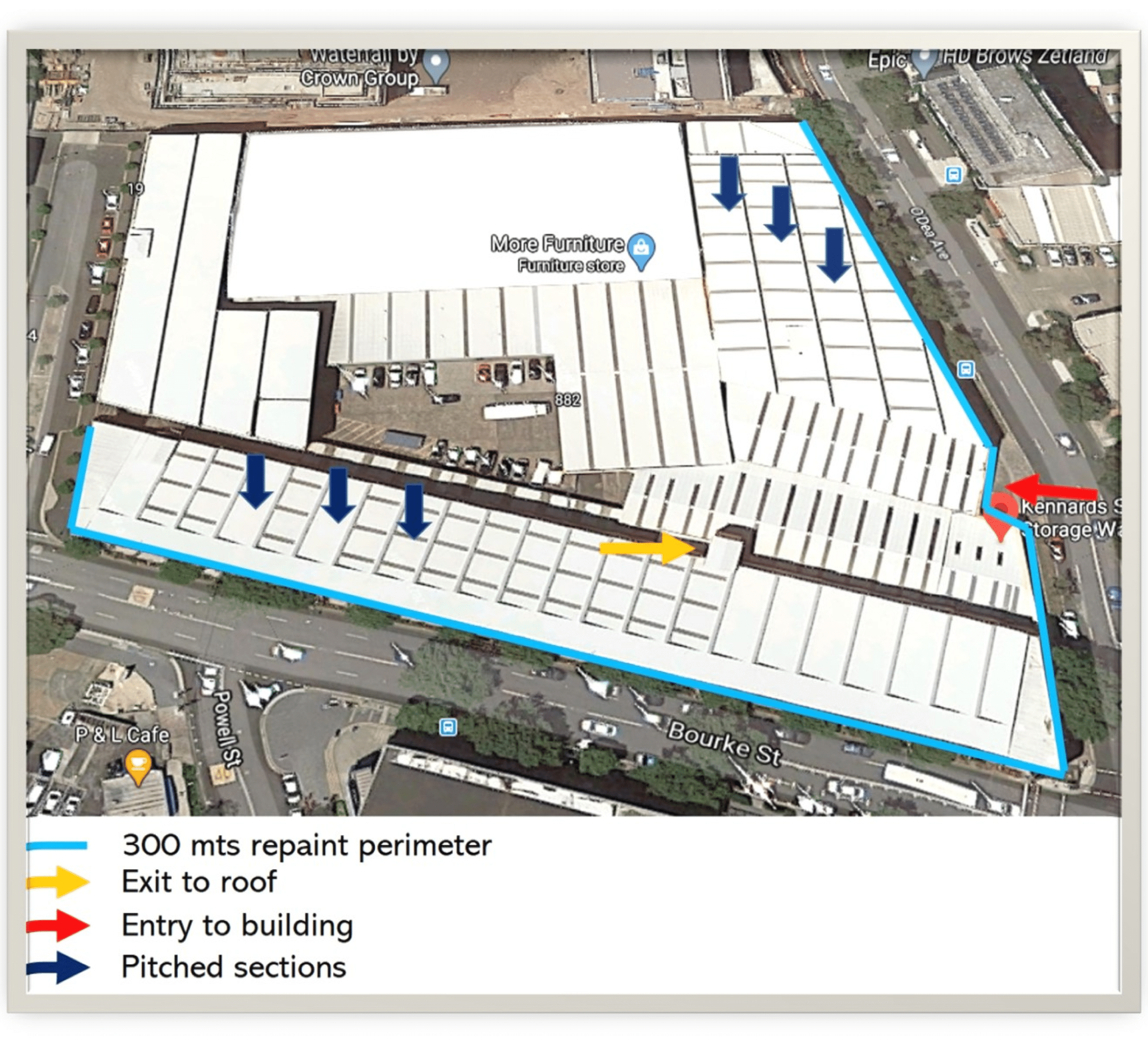

Lets first look at the facts (challenges) about the job:

- 4 Storey building (18 mts height approx.)

- Perimeter of the building where requires repainting: 300 mts approx.

- Only one entry to the building and very busy with customer traffic delivering and storing boxes all day long.

- Only one exit to the roof.

- Old slow lift to reach the top level plus extremely busy with the normal storage operations.

- Access to the roof from the top level is with an extension ladder.

- Roof area is not flat. It is an old Saw Tooth design and in many areas has pitched sections.

- 3 step process (One for cleaning and 2 coats of painting) which means 3 drops per every 2-meter section (This is what an abseiler would reach with 1 set of ropes).

- Estimated number of drops for the whole job is 300mts /2 mts = 150 x 3 steps = 450 drops to complete the job. This is a lot of drops!!

We can now start to imagine how challenging the works would have been if done by traditional abseiling where there would have been 2 options:

- To go back to the roof for every required drop (450 times) to abseil down, or;

- Ascend, which is basically climbing up the rope physically using ascender devices. See photo below.

The first option would have been a huge task and very costly in time, given that the distance tradesmen would have walked from the exterior of the building (with 300 mts of perimeter) to the only entry of the building, plus use the old slow lift and climb up the extension ladder (5 mts) from the top level to the roof .

However, option 2 is also time consuming and exhausting, as operators would have had to climb up a minimum of 4 times a day which is close to an 80 mts height. This is the equivalent to a 26-storey residential building ( and that’s before they did the job at hand!) With both options above the time taken to complete works would be very costly and the operators would have used most of their energy just to position themselves in the working area.

Because exhaustion highly increases the chances of making mistakes in the workplace , especially at heights, the added risk of failures and incidents such as dropping objects, not performing their corresponding height safety checks, potential fainting and others increase exponentially.

Fatigue is more than feeling tired and drowsy. In a work context, fatigue is mental and/or physical exhaustion that reduces your ability to perform your work safely and effectively.

However, option 2 is also time consuming and exhausting, as operators would have had to climb up a minimum of 4 times a day which is close to an 80 mts height. This is the equivalent to a 26-storey residential building ( and that’s before they did the job at hand!) With both options above the time taken to complete works would be very costly and the operators would have used most of their energy just to position themselves in the working area.

Because exhaustion highly increases the chances of making mistakes in the workplace , especially at heights, the added risk of failures and incidents such as dropping objects, not performing their corresponding height safety checks, potential fainting and others increase exponentially.

Fatigue is more than feeling tired and drowsy. In a work context, fatigue is mental and/or physical exhaustion that reduces your ability to perform your work safely and effectively.

Correspondingly CPR’s Pears ™ technology allows our tradesmen to work comfortable and safely at all times. We leverage the huge mechanical advantage provided by Pears™ and our other technologies and custom designs , so as our committed tradesmen can expend their energies carrying out the painting, rendering and cleaning tasks at hand to the highest quality standards.

The Portable Elevator Access Rope System allowed our team to finish the job in at least 50% less time than traditional rope access methods whilst minimising interruptions to our client and their business operations. Most importantly our team were well focused , utilizing their energy to provide the best finish in a safe and efficient manner.

CPR are proud of the 25 State Awards we have won for Excellence in Service, Workmanship and Safety. With over 20,000 delighted owners , we invite you to be the next one.